Hyundai Excavator Issues: 6 Common Issues Explained

페이지 정보

작성자 Naomi 작성일24-10-13 06:22 조회4회 댓글0건본문

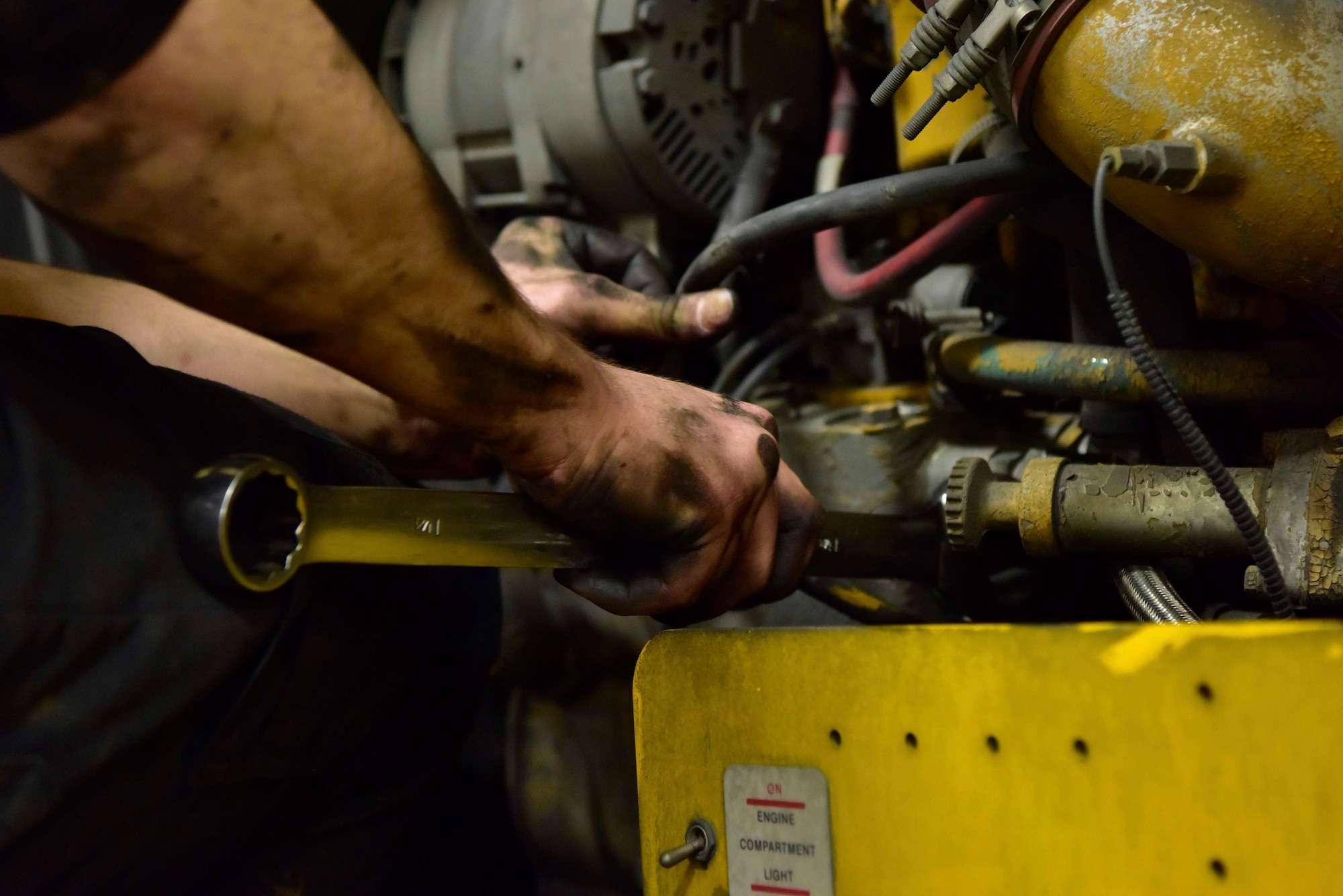

Exchange any broken ones. Tighten Connections: Ensure all connections between hoses, pipes, and fittings are secure. Use appropriate instruments to tighten them if essential. Monitor Fluid Levels: Keep a detailed eye on hydraulic fluid levels to detect any sudden drops which will indicate a leak. Regular Upkeep: Adhere to scheduled upkeep routines, together with regular oil changes and lubrication with quality grease. Everybody looks at the purchase value of a brand new piece of gear. However, with hammers, I additionally suggest that you discover out the price of resealing and rebuilding them. One of the incessantly neglected features that surfaced while researching our present fleet was that a few of the more competitively priced hammers actually had greater restore prices when it got here to elements and labor. Consider repairing or changing the suction line if the damage is extensive. Worn out hydraulic pump could also be the cause of your hydraulic system’s inoperative nature. Consider changing it. Also, verify if your excavator’s Hydraulic Breaker fluid is contaminated. If that's the case, replace it before utilizing your excavator. Worn components such because the valves may additionally make your excavator hydraulic system inoperative.

Our complete catalog is highlighted by a various range of Volvo Salvaged and Used parts, making certain our prospects have access to one of the best when it comes to high quality and reliability. Particularly, when we talk about Volvo Mini Excavator parts, items like Final Drives, H Hyperlinks, Hydraulic Cylinders, Swing Gear and Bearings, Axle Elements, and more should not just mere listings. Mini Excavator Hydraulic Pump creates pressure when power is supplied to the hydraulic motor, rotating its rotor. The rotor turns a shaft that has impeller blades attached to it on its finish. As the blades move from inside to outside of the pump housing, they compress the fluid touring by the tube and create pressure behind them. 6. What's the difference between a hydraulic motor and a Mini Excavator Hydraulic Pump? The distinction between hydraulic motor and mini excavator hydraulic pump are listed under.

Moreover, you will need to avoid using the breaker for duties that it is not designed for, as this can even lead to damage and reduced effectivity. Lastly, common upkeep and servicing by qualified professionals is crucial for hydraulic breakers. This contains periodic inspections, lubrication, and replacement of worn or broken parts. Instead of procuring an array of machinery for various duties, we can harness the multi-faceted utility of a mini excavator equipped with a rock breaker. This synergy ensures operational thriftiness and peak effectivity. The inherent compactness of mini excavators, when paired with a rock breaker for mini excavator, ensures that even essentially the most house-restricted job sites will be successfully tackled.

Overheating could cause some excavator components to blow up, which is costly to repair. Divide the load into manageable bits to forestall overheating and improve the excavator’s lifespan. A faulty exhaust system doesn’t let out the overheated exhaust fumes from vitality production, elevating the engine’s temperatures. Replacing a damaged system and cleaning all clogged exhaust pipes will resolve these issues immediately.Defective radiator caps let in excess air, causing the coolant to strain when flowing via the system and cooling the engine.

As such so that you can clear this obstruction off you're going to need plunging into and pulling out of this passage till it causes opening up that allows liquid flow throughout. Hydraulic Pump Seals Cups refers to 1 element utilized in a hydraulic system. To type a fluid tight seal between cups, there's a sealing lip located on the inlet side of one cup which engages with an annular groove situated on outlet aspect after one other cup. This seal prevents liquid from leaking previous these cups and permits pumps to work at high pressures. When seals fail in many circumstances they could result in dry run situations with hydraulic pumps. Filters are designed for highly environment friendly contaminant removing and lengthy life to keep up optimum efficiency of the machine. It’s additionally better to get excessive filtering capabilities as they are going to cease better than the low ones. Komatsu Air Filters: this is vital to have high performance and engine reliability. Komatsu Gas Filters: These are measured in microns and the filter have to be controlled to prevent the water and mud from getting in - Pre-Fuel Filter: this has a 10-micron score and a water separator.

댓글목록

등록된 댓글이 없습니다.